From Concept to Product

Design and

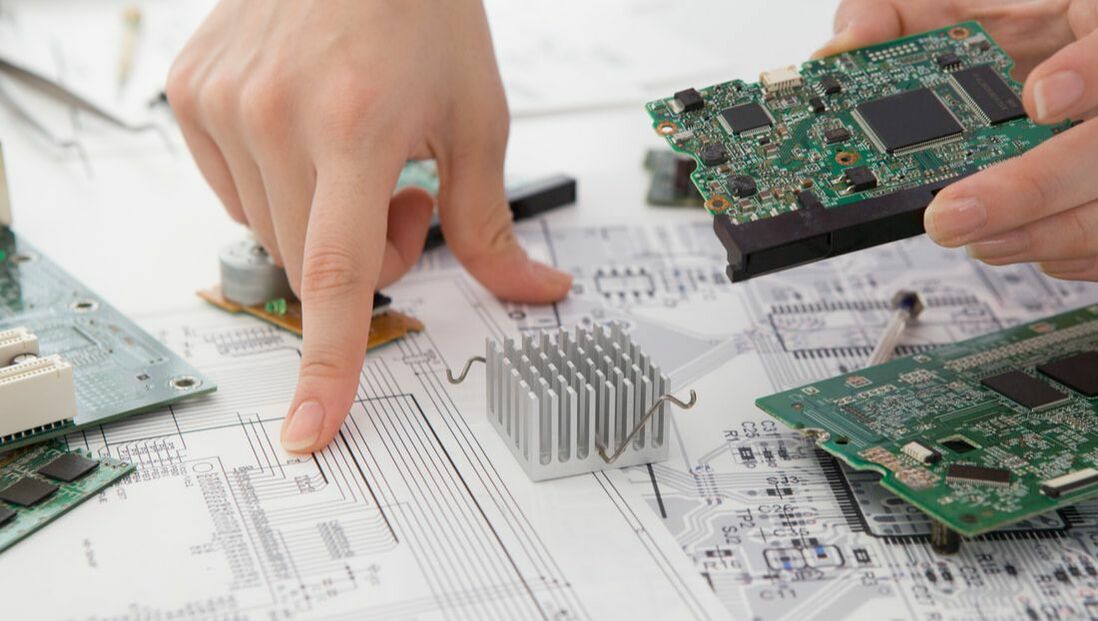

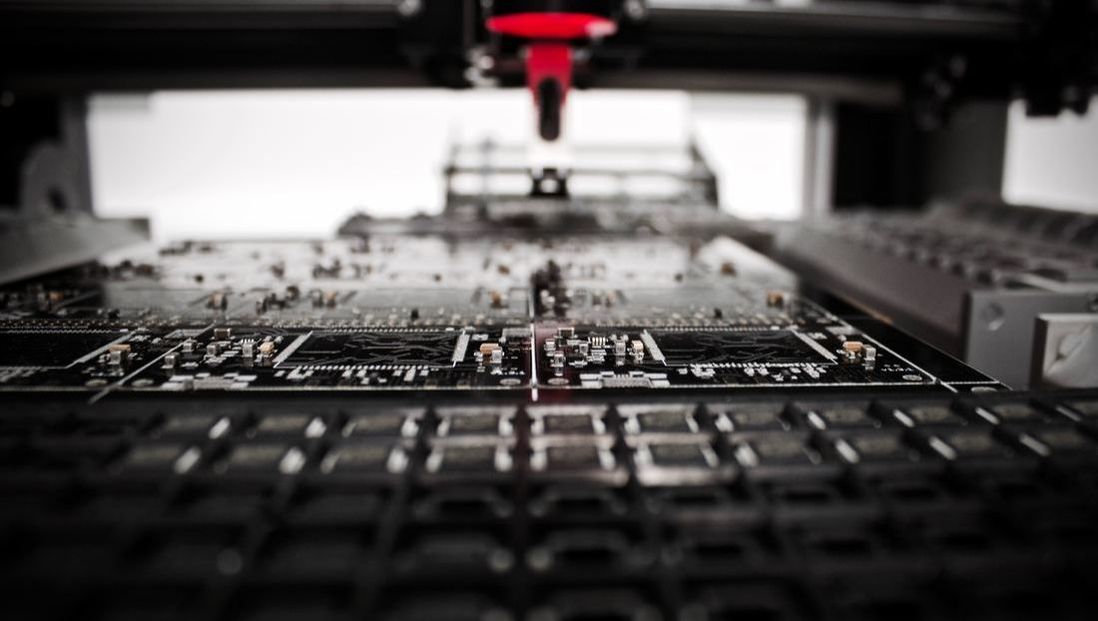

Our focus at Fringe is to work with our customers to build a long term partnership and our R&D team provide a design and development service from initial concept and design to product development, improvements and reverse engineering.

Prototyping is a big part of introducing any new product and something we are highly experienced in. We can offer small production runs for new products or as samples for you to critically review prior to placing orders. Key areas of design expertise include:

|

|